Air Classifier s mill product as finely as 5 μm ejec. Air Classifier Mill Machine Explained.

Air Swept Classifier Mill System How It Works Benefits Cms

MZM MZF Multi-Plex.

. The air classifier is used to select the onsize material and return the. From the moment of this founding. Obtain a budgetary quote and initial purchase order.

Regardless of the mechanical design features of a particular air classifier certain basic principles apply. They are ideal as a stand-alone process that includes a feeder and dedicated dust collection systemThey are. Air classifiers are often used in closed circuit with grinding mills such as ball mills hammer mills roller mills or jet mills.

Our air classifiers offer size separations in the range of 3 to 150 microns. Air Classification Working Principles. Ad Get The Air Classifier Mills Parts You Need Within 24 Hours Or Consult With Our Experts.

Classifiers Air Classifiers. F or over a century NNZoubov Engineers SMCE has been busily designing and producing classifiers which are among the best in the world. We connect buyers to the equipment they need easier and faster than they can on their own.

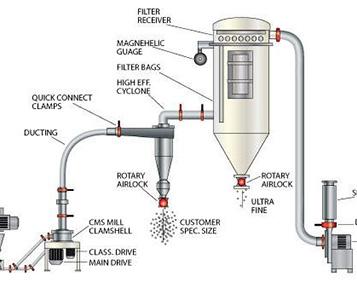

An Air Classifier Mill is used for milling and grinding heat-sensitive material and provides precise control over particle cut point selection by incorporating an internal air-classifying wheel and. The system uses an inert gas nitro-gen rather than air to safely handle a. Example air classifier mill system Figure 3 shows a vertical air classifier mill installed in a closed-loop system.

Air Classifiers AC Three types of separators each with a high-precision method of classifying particles according to size or density. Launched by Hosokawa in 1962 the original ACM Air Classifier Mill was the first mill of its type available and it continues to be a very popular choice with customers from many sectors. Its durability reliability and precision are.

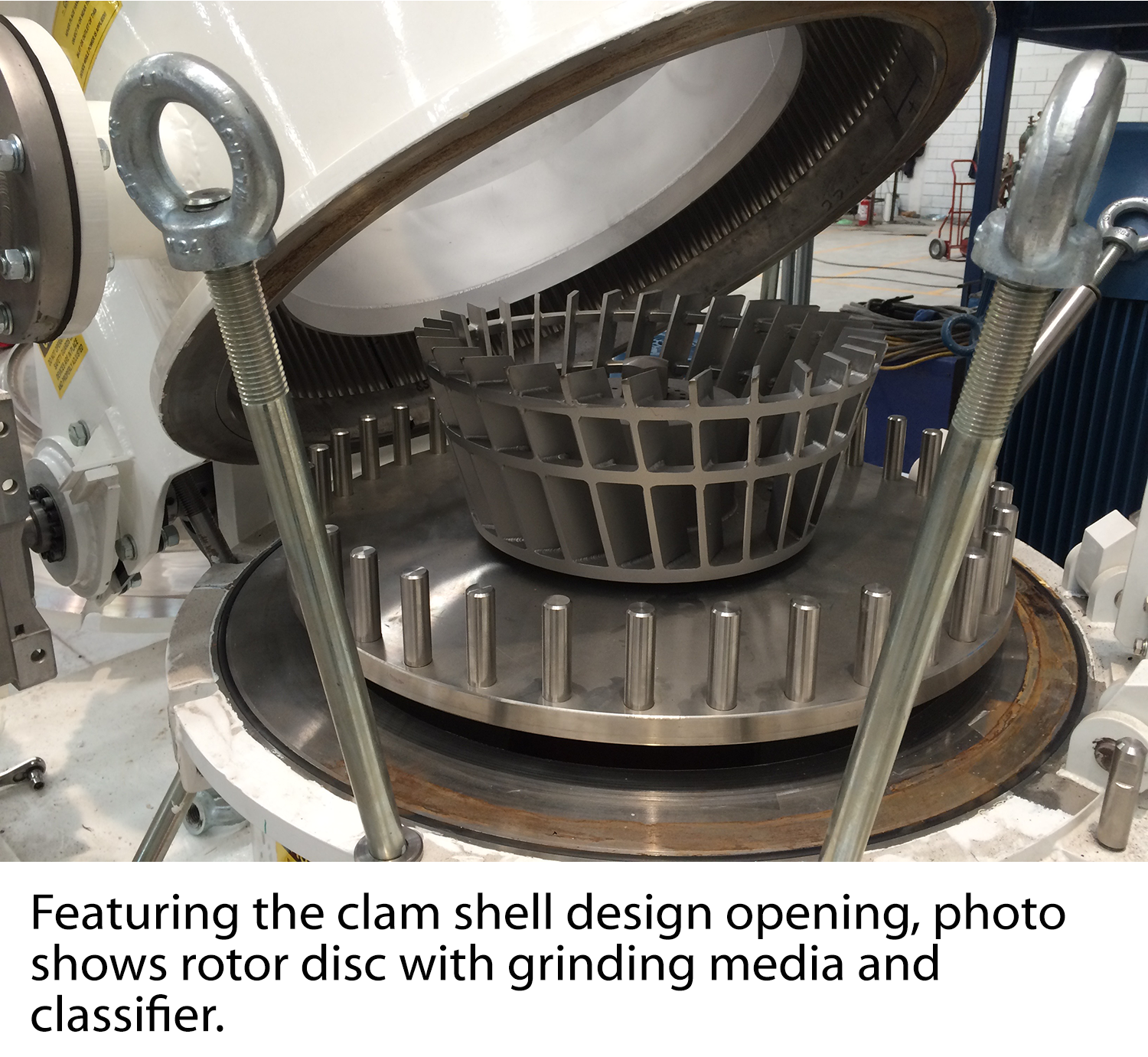

Cleaning and maintenance of the PPS Air. Ad Get great deals on used industrial commercial equipment. The ACM classifier mill was the first classifier mill on the market in 1962.

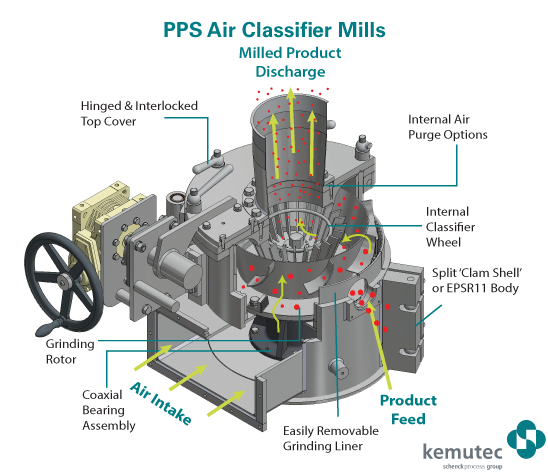

Classifiers Air Classifiers. The Mikro ACM Air Classifying Mill is an air swept mechanical impact mill designed u0003to grind a wide range of materials down to D97 20 µm. The PPS Air Classifier Mill Machine is a vertical grinding mill that incorporates an internal air classifying wheel with an independent.

Work with our engineers to determine the exact. Click to Request Price. In addition PPS Air Classifier Mills benefit from flexibility of design allowing systems to be customized to fit into all types of physical layouts.

Perform a trial run to determine feasibility and throughput needs recommended 3. Self-contained design wcyclone 2 air filters and co. Since then the ACM has been continuously developed and adapted to the changing needs of the market.

In addition PPS Air Classifier Mills benefit from flexibility of design allowing systems to be customized to fit into all types of physical layouts. We pursue the management tenet of Quality is remarkable Company is supreme Name is first and will sincerely create and. Specifically there are two.

Cleaning and maintenance of the PPS Air. Air Classifier Design - China Manufacturers Factory Suppliers. With the use of air flow gravity and sharp directional changes the gravitational classifiers perform accurate separations of material from 1700 microns down.

For dry materials of 100 mesh and smaller air. Ad Get The Air Classifier Mills Parts You Need Within 24 Hours Or Consult With Our Experts.

How Does A Pps Air Classifier Mill Work Kemutec

Operate An Air Classifier Mill To Meet Your Fine Grinding Goals Hosokawa Micron Powder Systems

A Complete Guide To Purchasing An Air Classifier Aveka

Micron Labomixer Lv Laboratory Analytical Instruments Hosokawa Micron Powder Systems Plant Automation Technology

Air Classifier Mills Solidswiki

0 komentar

Posting Komentar